MATERIALS for IDEAS

REALIZE IDEAS

Today Composite components allow you to think in dimensions which still were unimaginable some years ago. Fiber compounds and its excellent abilities meet us in many situations in everydays life and accelerated and influenced the technical developments extremely. If aircraft construction, automotive industry, medical technics, sports or leisure, there is nearly no field where the advantages and possibilities of composites don’t take effect.

SURVEY OF PROCESSES

LFI LONG FIBER INJECTION MOULDING WITH REACTIVE PU

PROCESS

Glass fiber rovings are cut at the mixing head directly and then brought in the open tool together with polyurethane. The hardening happens in the closed tool.

MAIN ADVANTAGE

Light components with high impact strength not only in automotive industry

ADVANTAGES

High quality surfaces by simple process combinations (IMP, foil)

High strength values (fiber portion till 50 percent, fiber length 12,5 – 100 mm)

Moderate tool- and installation cost

CHARACTERISTICS

Fiber content and length locally adjustable

Easy integration of inserts (e.g. inserts and fixing elements)

Favourable basic materials, minimum fiber waste

Characteristic profile similar to SMC at lower weight

APPLICATION FIELDS

Hoods, roof elements, side coverings, coverings, flaps, dash boards

ANNUAL QUANTITIES

10.000 to 120.000 pieces

PRODUCT

LFI-ROVING MULTISTAR® 576

Advantages: suitable for highspeed working, dust reduced cutting behaviour. PU size for very good fiber-matrix-adhesion

Packing: Splicing on clients request

The LFI process is a continuous process with heavy demands on the used raw materials. Here the glass fiber roving is of great importance: With partly very high speed the roving strain is guided to the cutting device by tubes and hereby it must maintain its compact shape. The cutting device determines different fiber lengths but also the fiber content. Supposition is here a very good cutting ability of the roving.

But it shouldn’t be „too hard“ and so cause negative endurance of the cutting tools. After cutting the roving strain must disperse in its single filaments in the air stream.

Lumping, so-called „snow balls“, or filament dust can block this process resp. pollute the surfaces of the surroundings. Instead of this the roving strain should decompose most homogenous so that it can be brought in the open tool in a focused atomizing cone in exact position and reproducible.

Because of the very short process cycles glass fibers further must interlace extremely fast with the PU, to achieve the high mechanical strength of the component. Corresponding PU-components in the size enforce this cross linkage.

PU-SANDWICH BAYPREG® / SCS WITH REACTIVE PU

PROCESS

A prefabricated sandwich of chopped strand mat/cardboard comb core/chopped strand mat is sprayed with PU mixture and deposited in the tool; shaping and hardening in the closed tool.

MAIN ADVANTAGE

Low component weight at high flexural- and compression strength

ADVANTAGES

Optimized light construction for moderate strength

Low operating cost, low material consumption

On both sides high quality finish surfaces possible

CHARACTERISTICS

On both sides spray of fibermat in a fixing frame

Simple combination with surface decoration in the tool

Light components with comb core

APPLICATION FIELDS

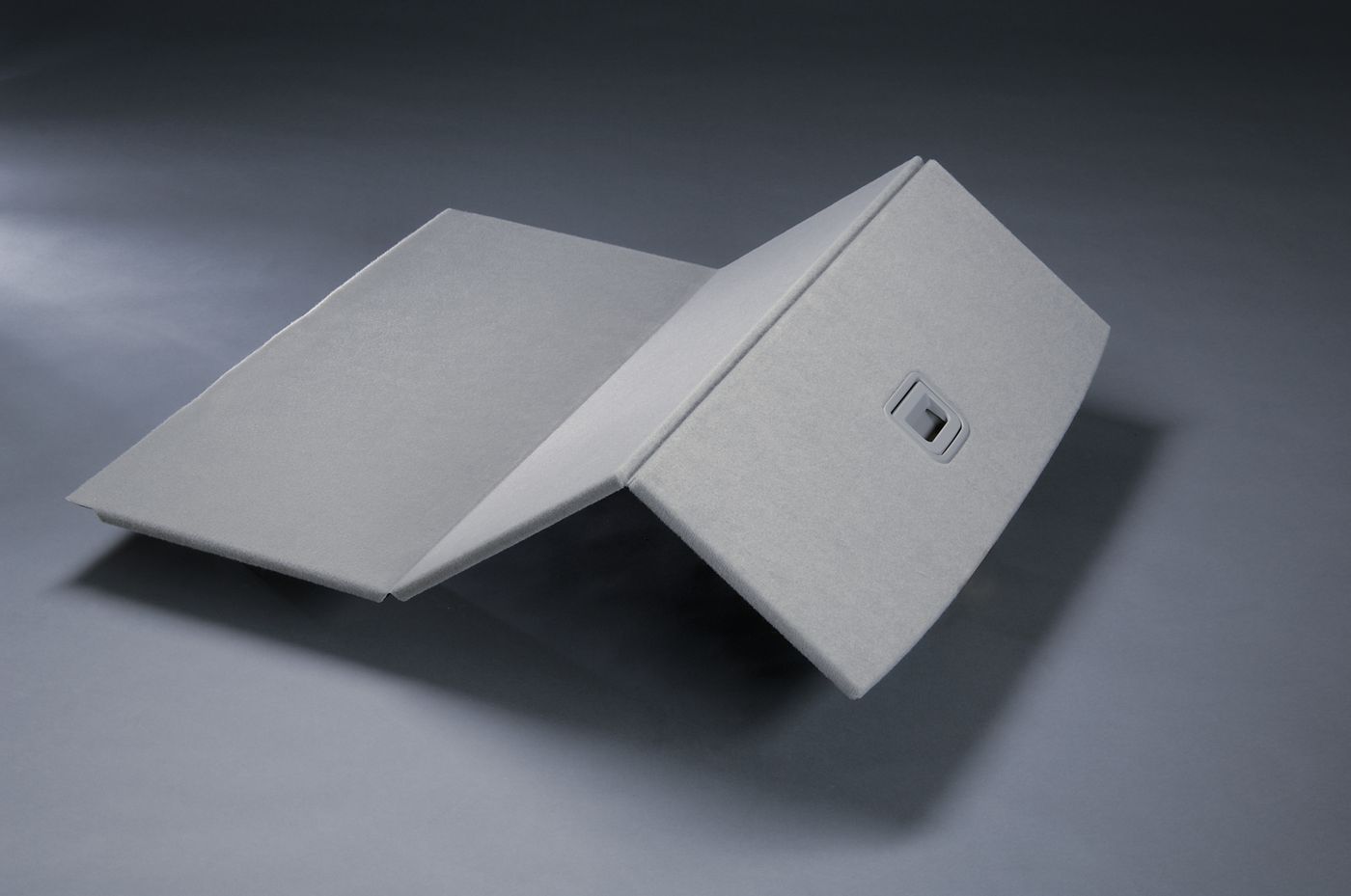

Hat racks, loading floors, laminated extensive components, sliding roof

ANNUAL QUANTITIES

10.000 to 300.000 pieces

PRODUCT

CSM-FI AUTOMOTIVE / CSM AUTOMOTIVE PU AND EM / ALL CSM-PRODUCTS / NEEDLE MAT

SM-FI AUTOMOTIVE: highly fine fiber filaments, from 100 g/m², powder bound

CSM AUTOMOTIVE PU AND EM: powder- or emulsion bound, from 225 to 900 g/m², for PU optimized size.

ALL CSM-PRODUCTS: low tolerances in basis weight and binder content, exact edges, big bobbins on client’s request, proportionated fiber face from the very beginning, width from 10 to 360 cm, high mechanical dry strength, optimized for automized processes, big rolls to 1000

NEEDLE MAT: binder free mat, stretchable, for strong outlines and crimps

An automized produced sandwich construction where the fiber mats with a high dry strength lay outside on a cardboard comb core, is sprayed with non-reinforced PU on both sides. Then the sprayed sandwich will be laid into the tool which then will be closed. A very proportionated fiber distribution is supposition for a fast matrix distribution and later homogenous surface of the moulded part. The fiber mats will be impregnated with PU whilst pressing process and whilst hardening the mats glue together with the fiber core. Binder, optimized for PU, care for a fast fiber/matrix adhesion and high mechanical strength.

Considering the material characteristics and the geometry extremely light components with extremely high flexural- and compression strength are created with harmonized supporting- and core layers.

RTM AND RTM LIGHT - RESIN TRANSFER MOLDING

PROCESS

RTM: unsaturated fiber mats or multi layer fabrics are injected with resin in the closed mould.

RTM LIGHT: stands for a low pressure injection with additional vacuum support

MAIN ADVANTAGE

Highly strength structure components for individual applications

ADVANTAGES

Optimized mechanical strength

Professional high quality finish, class-A-surfaces

Good reproducibility

Moderate investment in installation- and mould construction

Production of small series

Uniform wall thickness

Lighter components than in hand process

CHARCATERISTICS

Ideal for small and middle series

More proportionated production compared with hand laminate

APPLICATION FIELDS

Motor sports, individual buildings, architecture

ANNUAL QUANTITIES

Up to 100 pieces

PRODUCT

EPOXY RESINS / POLYESTER RESINS / FABRICS OF GLASS- AND CARBON FIBERS

EPOXY RESINS: with component optimized viscosity and reactivity, highly transparent, UV-resistant

POLYESTER RESINS: on orthophtalic or isophthalic base, low viscous and styrene poor, also suitable for fire protection (halogenous free)

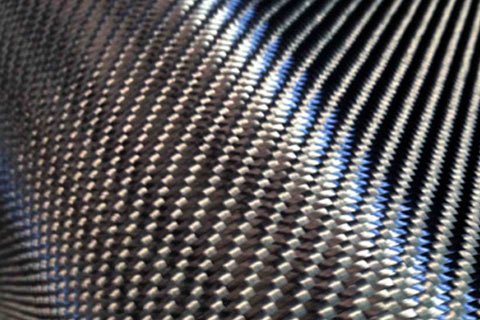

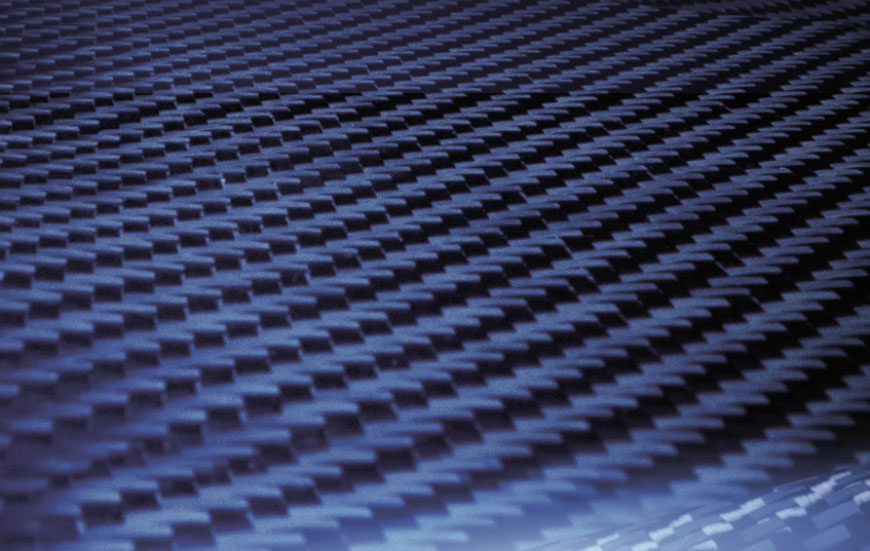

FABRICS: of glass- and carbon fibers (also unidirectional)

MULTI LAYER FABRICS: uni- or multiaxial of glass- and carbon fibers

NONWOVENS: for class-A surfaces

3D-CORE: tridimensional drapable core material

FLOW AIDS / DISTANCE SUPPORT: like textile knitted fabrics and nonwovens of glass fiber, PP and PES

Unsaturated reinforcing fibers eventually in form of pre-ready made and outline near preforms will be laid into the tool. After closing the mould the reactive resin system will be injected and flows through the fiber layers. After impregnation excess resin flows out at the ventilation.

Mostly the matrix consists of duroplastic plastics like polyester, epoxy- or phenol resin.

Using high reactive resin systems it’s possible to reduce the cross linkage time under 3 minutes and to realize so short cycle times in RTM-process.

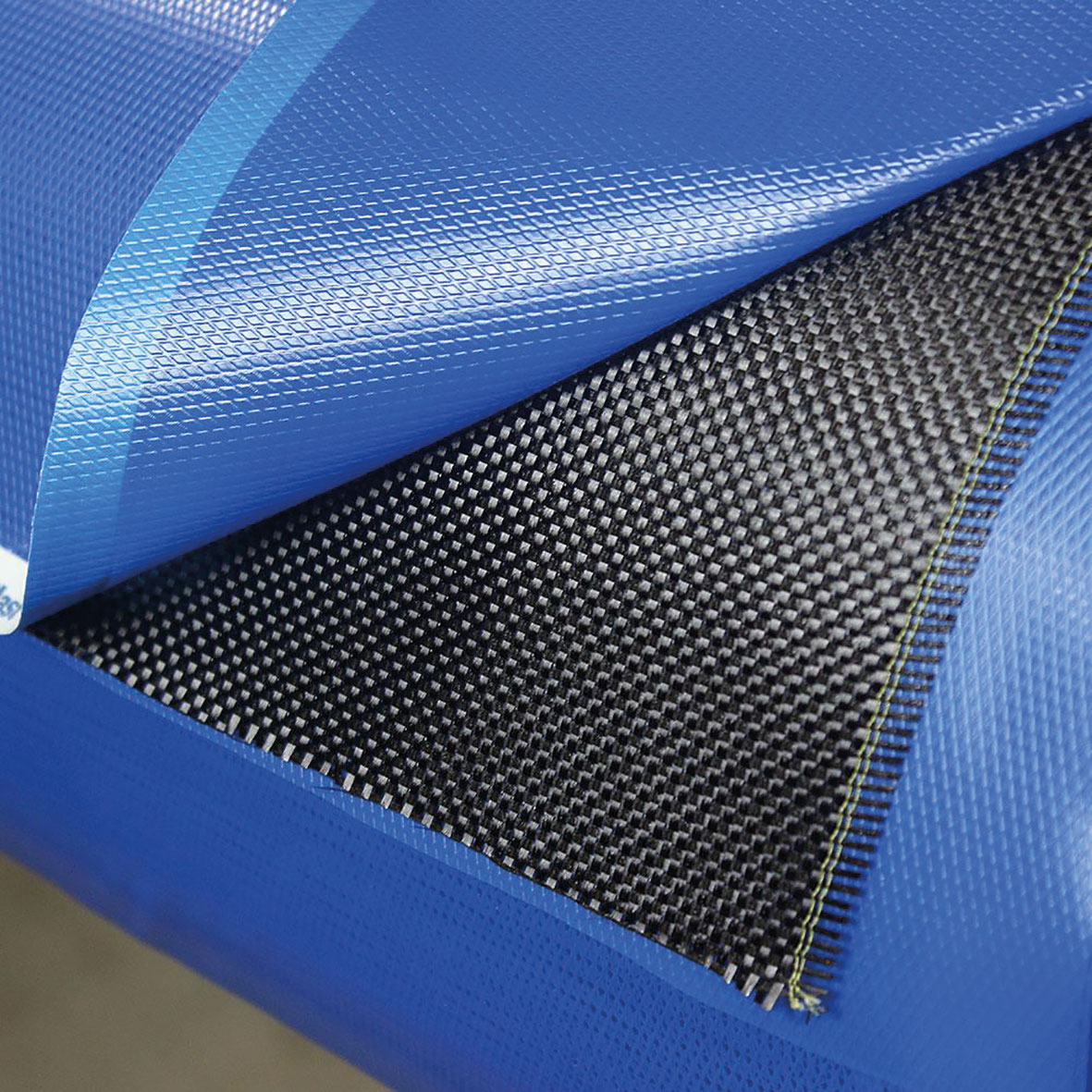

As fibers are used glass fibers, carbon fibers and also fibers of polymer materials like aramid- and polyethylene fibers. Hereby the fiber rovings can be worked to different fiber half-finished goods with different architecture.

Besides multi layer fabrics, fabrics, nonwovens and mats also knitted fabrics and plaitings are used for the production of components of fiber reinforced plastics.

HD-RTM / C-RTM HIGH PRESSURE / COMPRESSION RESIN TRANSFER MOLDING

PROCESS

HD-RTM: Pre ready-made fiber mats or fabrics will be laid into the tool. After closing happens the resin addition and the reaction in the closed tool.

C-RTM: Fiber mats and fabrics will be laid into the tool. Resin addition happens in the tool that is opened a slit and the reaction then in the closed tool.

MAIN ADVANTAGE

Very light, highly strong high-performance-light components

ADVANTAGES

Light components for highest requirements. Ca. 50% more light than steel

Visible components with high quality carbon optics

Components which can be varnished for visible applications

Full automation possible and suitable for series production (from pre-form manufacturing till rework)

CHARACTERISTICS

Nearly unidirectional reinforcements with continuous fibers possible

High pressure technics allow the use of fast reacting systems

High fiber portions of up to 50 percent

APPLICATION FIELDS

Structure components, side walls, both tubes, bumpers, crash boxes, carbon design parts

ANNUAL QUANTITIES

10.000 to 120.000 pieces

PRODUCT

FABRIC AND MULTI LAYER FABRICS OF GLASS- AND CARBON FIBERS / NONWOVENS FOR CLASS A SURFACES

FABRIC: of glass- and carbon fibers for thermo- and duroplast matrix (also unidirectional)

MULTI LAYER FABRIC: uni- or multiaxial of glass- and carbon fibers

NONWOVENS: for class A surface

FLOW AIDS / DISTANCE SUPPORT: like textile knitted fabrics and nonwovens of glass fiber, PP and PES

In HD-RTM-process [high pressure resin transfer molding] a fiber preform of glass- and/or carbon fibers will be built up. The composition happens orientated on the demand corresponding to the load of the later structure component. This preform will be laid into the tool, which will be closed and evacuated then. After that a very low viscous, reactive epoxy resin, polyurethane or cast polyamide will be injected into the cavity to moisten so each single fiber without air inclusions.

The C-RTM process (Compression Resin Transfer Molding) mainly differs from HD-RTM process, that the resin mixture will not be put into the closed but into the tool with open gap. This means that the tool isn’t closed completely whilst filling. So the preform already becomes partly perfused with resin. After filling happens a compression lifting which causes that the resin will be pressed through the preform and so becomes perfused completely.

Excellent strength: In HD-RTM process extremely light structure components for highest requirements are realized that appear for example in automobile crash tests. It’s already established in the aerospace industry, in engineering industry and in automobile industry. In HD-RTM process fiber contents of 50 percent are achieved.

HOT PRESS AND AUTOCLAVE PROCESS OF PREPREGS

PROCESS

Prepreg is the short form of „Pre-impregnated Fibres“, so with epoxy- or phenol resin pre-saturated fabrics and multi layer fabrices out of carbon-, glass-, aramid- or hybride fibers. Different prepreg systems are existing depending on process and use. The prepregs will be inserted into the mould and wrapped with punched foil, suction nonwoven and foil before these are pressed under vacuum or in autoclave.

MAIN ADVANTAGE

Calculable components with an optimum component weight at maximum strength

ADVANTAGES

Process security

Short cycle times

Dimsensionable fiber volume and component weight

Clean working

Minimum danger of allergy

CHARACTERISTICS

Defined and so optimzed fiber-/resin portion

Very good strength values at extremely light weight

Uniform wall thickness

Low ondulation and high fiber volume portion

APPLICATION FIELDS

Aerospace, automotive, engineering industry, industrial components and production of heavy duty sports equipment.

ANNUAL QUANTITIES

From 10 pieces (e.g. prototype construction) till 1.000 pieces in series production

PRODUCT

PREPREG / 3D-CORE / NONWOVEN FABRICS

PREPREG: for all processes

3D-CORE: tridimensional drapable core material

NONWOVENS: for Class A surfaces

Pre-saturated fabrics will be laid into the mould / the tool. Then separating-/punched foil and suction nonwoven will be laid on the prepreg that excess resin can be sucked off under pressure of 1 bar – 30 bar (depending on application). As moulds normally carbon- (e.g. produced of special tooling prepreg) or steel pressing moulds are used. Depending on the requirements to the component or the processes different prepreg systems are used:

Low temperature prepregs: Working at a pressure till 1 bar and temperatures from 75°C

Autoclave- and hot press prepregs: Working larger than 1 bar - 20 bar and at temperatures from 80° C to 180° C depending on the application field. In hot press process no foils or suction fabrics are used.

Tooling prepregs: Working in the autoclave from 2 bar to 30 bar and temperatures from 120°C to 200° C.

FIBER WINDING / PULTRUSION

PROCESS

In pultrusion process fiber glass rovings are torn into moulding tools which are tempered.

MAIN ADVANTAGES

Tanks and tubes for modern driving technics

ADVANTAGES

Essential weight advantage compared to steel

Corrosion- and UV protection

CHARACTERISTICS

High design freedom

Till 80MPa internal pressure

Low production costs

APPLICATION FIELDS

High pressure gas container for natural gas drivings, primary shafts, plate springs

ANNUAL QUANTITIES

10.000 to 120.000 pieces

PRODUCT

EPOXY RESINS / POLYESTER RESIN / STARROV® 086 / STARROV® 908 / ECR-ROVINGS / NONWOVENS

EPOXY RESINS: with component optimized viscosity and reactivity, highly transparent, UV-resistant

POLYESTER RESINS: on orthophtalic or isophtalic base, low viscous and poor of stryrene, also for fire protection (halogenous free)

STARROV® 086: for UP-, EP- and VE-resins, very soft silane size, nearly free of fluffs

STARROV® 908: for UP-, EP- and VE-resins, stress free draw off, fast perfusion

ECR-ROVINGS: for application in corrosive surroundings

NONWOVENS: of E- and ECR-glass, to protect surfaces from corrosion

In open pultrusion processes the fiber rovings are led into a resin bath or the impregnation installation. The fibers pass several preform stations, so that they are led to the requested profile shape. Mats, fabrics, multi layer fabrics or nonwovens can be integrated in the process at the fiber guidances to adapt resp. to optimize the mechanical characteristics against a pure unidirectional reinforcement as it’s achieved by fibers.

At the so-called closed process all the reinforcing fibers only get in contact with the unhardened monomers in the moulding tool, but then with increased pressure for a better impregnation. In the tool the monomer reacts to the polymer. The hardened semifinished products is be pulled through a caterpillar haul-off and so also pulls on the fibers along with the matrix.

INJECTION MOULDING (LFT) SHORT- AND LONG GLASS FIBER REINFORCED THERMOPLASTS

PROCESS

Many thermoplast granulates for injection moulding machines are reinfored with short chopped glass fibers to increase the mechanical charactistics clearly. In LFT process with fiber lengths up to 25 mm still much higher mechanical characteristic values are achieved.

MAIN ADVANTAGES

Injection moulding for fiber reinforced compounds

ADVANTAGES

Short cycle times allow a full automatic production of high piece numbers

By fiber portion improved meachnical characteristics and high rigidity

Combinable with nearly all variants of injection moulding process

CHARACTERISTICS

With light modifications standard injection moulding machines can made fully automatic

Working and process are well-known

Recompound utilization

APPLICATION FIELDS

Seats, dashboards, door modules, technical parts in the motor room

ANNUAL QUANTITIES

300.000 to 600.000 pieces

PRODUCT

ALL THERMFLOW®-FIBERS / STARROV® 490 / TECHSPHERES / TECHBEADS

THERMOFLOW® 672: for PA and PA 6.6: maximum tensile- and impact strength; no drop of nominal values with stearates

THERMOFLOW® 675: for hydrolysis resistant PA

THERMOFLOW® 636: for PP: best mechanical and dynamical values, suitable for uncoupled PP

THERMOFLOW® 601: for POM, PBT, PC and PF

THERMOFLOW® 768: for high temperature polymeres PEEK, PES, PPS, PEI a.o. ALL

THERMOFLOW®-FIBERS: directly chopped fibers, very good dosage, high apparent density, neutral colour in the compound, Big Bag and Oktabine-packaging

STARROV® 490: for LFT PP

TECHSPHERES / TECHBEADS: Microglass balls with silane coupling agent

To achieve a higher component rigidity, many technical thermoplasts like PA, PP a.s.o. are reinforced by short cut glass fibers which are especially modified for the respective matrix. The compounds ready for working normally have a fiber portion of 15 to 50 weight percent, but supposition is that the fibers have good pourability and so can be dosed exactly. Further client-specific requirements like hydrolysis- or high temperature resistance are special characteristics of glass fibers for thermoplast reinforcement.

All this also can be achieved with longfiber reinforced thermoplast granulate (LFT) at lower fiber content and so lower weight. The length of the fibers corresponds to the granulate length, common are fiber lengths of 12 and 25 mm. LFT with higher fiber portion are preferred used for non-visible semi-structure components like frontends and dashboards. These components require a high impact strength, to bear also vibrations and shocks. On principle LFT components have less fiber orientation, since the long fibers are blocking each other.

DIRECT-COMPOUNDING (D-LFT)

PROCESS

The D-LFT process connects the continuous compounding of extrusion technics with the discontinuous injection moulding. So longfiber reinforced thermoplast components with better characteristics can be produced less expensive than from granulate.

MAIN ADVANTAGE

D-LFT combines compunding and injection moulding – ideal for bulk series

ADVANTAGES

Short cycle times allow the full automatic production of high piece numbers

Improved mechanical characteristics and high rigidity by long fibers

Favourable material cost

CHARACTERISTICS

Process highly to automate

Flexible adjustable on requirements

Material mixture of favourable standard raw materials

APPLICATION FIELDS

Frontend carrier, gear carrier, spray walls, battery tank

ANNUAL QUANTITIES

300.000 to 600.000 pieces

PRODUCT

STARROV® 490 / STARROV® 890 / TECHSPHERES / TECHBEADS

STARROV® 490: for D-LFT PP

STARROV® 890: for D-LFT PA

TECHSPHERES / TECHBEADS: Microglass balls with silane coupling agent

Glass fibers in form of rovings whose size is adapted to the respective compound are torn into the extruder and impregnated with the already melted matrix polymers. Whilst this they were shortened and then transferred into an injection ram. The continuous melting process assures steady material quality.

Compared with the LFT granulate the direct compounding in D-LFT is much more favourable because of no necessity of granulating and cooling as also glow energy- and material costs. Moreover the mechanical characteristics are essentially better by the lower fiber damage and only single melting phase.

ORGANO SHEETS

PROCESS

Organo sheets are plane semifinished products of a thermoplastic plastic matrix, which are reinforced with a fabric or multi layer fabric mostly out of glass fibers, what cares for a high mechanic strength of the component. Organo sheets are transformed to tridimensional parts by heating and then pressing in very short cycle times in a purely physical way – similar to the deep drawing of sheets, what explains the name „Organo sheet“.

MAIN ADVANTAGE

Thermoplastic structure components with function integration

ADVANTAGES

Defined rigidity, strength and heat expansion better than at the metallic patterns

High potential for the constructive shaping

Short cycle times similar to injection moulding

Full automatic production process

Components with end contour from the injection moulding tool (no necessity of rework)

CHARACTERISTICS

Thermoplastic components with defined continuous fiber reinforcement

Large weight saving potential without cuts in functionality

Fiber volume portion >50%

Production process highly to automate and to reproduce

High function integration possible

APPLICATION FIELDS

Frontends, seat shells and - backs, dashboards, floor groups, technical parts in the motor room, semifinished structure components

ANNUAL QUANTITIES

200.000 to 500.000 pieces

PRODUCT

HYBRID GLASS FIBER ROVING / FABRICS AND MULTI LAYER FABRICS OF HYBRID GLASS FIBERS / SEMIFINISHED PRODUCTS

HYBRID GLASS FIBER ROVING: with polypropylene matrix (PP)

FABRICS: of hybrid glass fibers according to client’s specification, also in UD

MULTI LAYER FABRICS: of hybrid glass fibers, uni- or multiaxial according to client’s request

SEMIFINISHED PRODUCTS: unidirectional with PP- and PE-matrix

Fabrics or multi layer fabrics of continuous fibers in thermoplastic matrix will be heated, transformed in the injection moulding tool and eventually relief-sprayed. So additional stiffenings can be realized by ribs and further functions can be integrated. The cycle times correspond to the common values with ca. 60 seconds and are determined essentially by the cooling phase in the tool.