FIRE PROTECTION - MATERIALS FOR SAFETY

REALIZE IDEAS

As one of less suppliers Mühlmeier Composites can offer a certified and perfectly harmonized fiber compound system international. The single components of the polymer matrix are exactly harmonized and certified as complete system. The so created fiber compound is flame retardant, with low toxicity and impresses by low smoke production in case of fire contact. In connection with national and international certification for the complete system we are able to offer here an outstanding product line. Especially in the field of transports it’s our main goal being able to offer save products that can protect man and technics from flames in case of emergency.

Your advantages

- certified complete system

- extreme resistance and high flexibility

- various use- and application possibilities

- material- and weight saving by light components

- at once ready for use

- confirmed fire resistance

- continuous control according to ISO test standards

Our innovative fire protection systems are available in three different recipes for the most important working processes: Hand laminating and spraying process, vacuum compressing and the injection process RTM resp. RTM light. The on that harmonized gelcoats protect the laminate from chemical and mechanical influences as well different weather, UV radiation or also moisture. Obviously these are deliverable in nearly all RAL colours.

For this we offer the suitable fiber reinforcement in form of mats or fabrics/multi layer fabrics and combinations from it. Especially for the injection- and RTM-process the FLOWMAT FR® - triple compound (chopped fiber-glass knitt fabrics-chopped fiber) of 100% glass fiber – was developed.

This compound is non-combustible and guarantees a delay-free resin flow also in an extremely filled matrix system. Nonwovens of glass fiber guarantee a high quality surface finish.

Our fire protection systems can be used in most different fields. Besides the various applications in building industry these are especially predestinated for naval industry, in the field of energy – especially wind energy – and obviously the various applications in transportation like rail traffic, mountain railways and buses.

RESIN COMBINATIONS

R921A – FIRE PROTECTION RESIN FOR RTM-AND VACUUM PROCESS

R921A – Fire protection resin based on unsaturated polyester resins. It is pre-accelerated, filled with minerals as well adjusted thixotrope and obviously halogenous-free. R921A neither contains a hardening indicator nor wax or paraffin and therefore it doesn’t cause any delamination.

Very high fire resistance, low toxicity and flue gas development as well low shrink behaviour are the special merits of this resin. Excellent mechanical values result from the special chemical composition and it’s easy to handle. It’s worked in fiber spraying process and also RTM.

FIRECARE R930A – FIRE PROTECTION RESIN FOR OPEN PROCESSES

R930A – Fire protection resin based on unsaturated polyester resins. It is pre-accelerated, filled with minerals without hardening indicator resp. wax or paraffin and obviously halogenous-free. The thixotropy contributes to the fact that only low sedimentation of the fillers appears and mixing before use becomes easier. Easy working and also very good mechanical characteristics were important criterions whilst development, which became reality with a special resin recipe. R930A offers excellent fire resistance and low fuel gas emission. Hand-lay-up process and also fiber spraying is recommended.

FIRECARE-FIRE PROTECTION SYSTEM

FIRECARE-Fire protection system consists of the halogenous-free polyester resin FIRECARE R930A

with FIRECARE GEL H07 as gelcoat. It’s a filled and thixotrope adjusted polyester resin without hardening indicator and a low sedimentation of the mineralic fillers. The high-grade gelcoat H07 is available in spray- and brushable version and stands out for high gloss, less yellowing and a wide range of colours. Both components can be worked without problems and fast without special requirements on the production process. Because of the excellent mechanical values laminate composition can be optimized and so also difficult construction parts can be realized definitely more dimension stable, more thinwalled and therefore with reduced weight.

The FIRECARE fire protection system offers an excellent fire resistance, low toxicity and fuel gas emission and so fulfills the most important European test standards!

PRODUCT NAME | Fire protection resin 921A | FIRECARE-Fire protection system

| ||||

|---|---|---|---|---|---|---|

RESIN BASE | UP | UP | ||||

HALOGENOUS-FREE | ||||||

FLAME RESISTANT | ||||||

PRE-ACCELERATED | ||||||

THIXOTROPE | ||||||

HARDENING | 1,5% MEKP | 1,5% MEKP | ||||

GELIFICATION TIME (25°C) | 16 - 27 MIN | 15 - 27 MIN | 15 MIN | |||

VISCOSITY RESIN AVERAGE VALUE | 900 MPAS | 1100 - 1400 MPAS | 5500 MPAS SPRAY, | |||

| VOLATILE PORTION | <30% | <15% | ||||

| MECHANICAL CHARACTERISTICS* | TENSILE STRENGTH | 147 MPA | 124 MPA | |||

E-MODULUS | 10,07 GPA | 11,09 GPA | ||||

ELONGATION AT TEAR | 2,40% | 2% | ||||

IMPACT STRENGTH | 86 KJ/m² | 86 KJ/m² | ||||

| FIRE PROTECTION CERTIFICATIONS | EN 45545 | > HL1: R1, R2, R3, R7 bis R17 | HL1, HL2, HL3: R1 | |||

DIN 4102-1:1998-05 | B1 | |||||

IMO FTP | ||||||

AFNOR NF F 16-101 | F0 | F1 | ||||

AFNOR NF P 92-507 | M2 | |||||

| REFERENCES | INSTALLATION BUILDING | |||||

BUILDING INDUSTRY | ||||||

ENERGY (WKA ETC.) | ||||||

NAVAL INDUSTRY | ||||||

TRANSPORT | ||||||

| WORKING PROCESSES | HAND LAMINATE | |||||

FIBER SPRAYING | ||||||

RTM | ||||||

VACUUM PROCESS | ||||||

| RECOMMENDED FIBER REINFORCEMENT | CHOPPED STRAND MAT | |||||

ROVING FABRIC | ||||||

MULTIAXIAL FABRIC | ||||||

FLOWMAT FR® | ||||||

SPRAY ROVING | ||||||

GLASS NONWOVEN | ||||||

*Laminate construction: 4 layers CSM450, resin/glass proportion 69:31, laminate heated up 24 days + 2h at 100°C

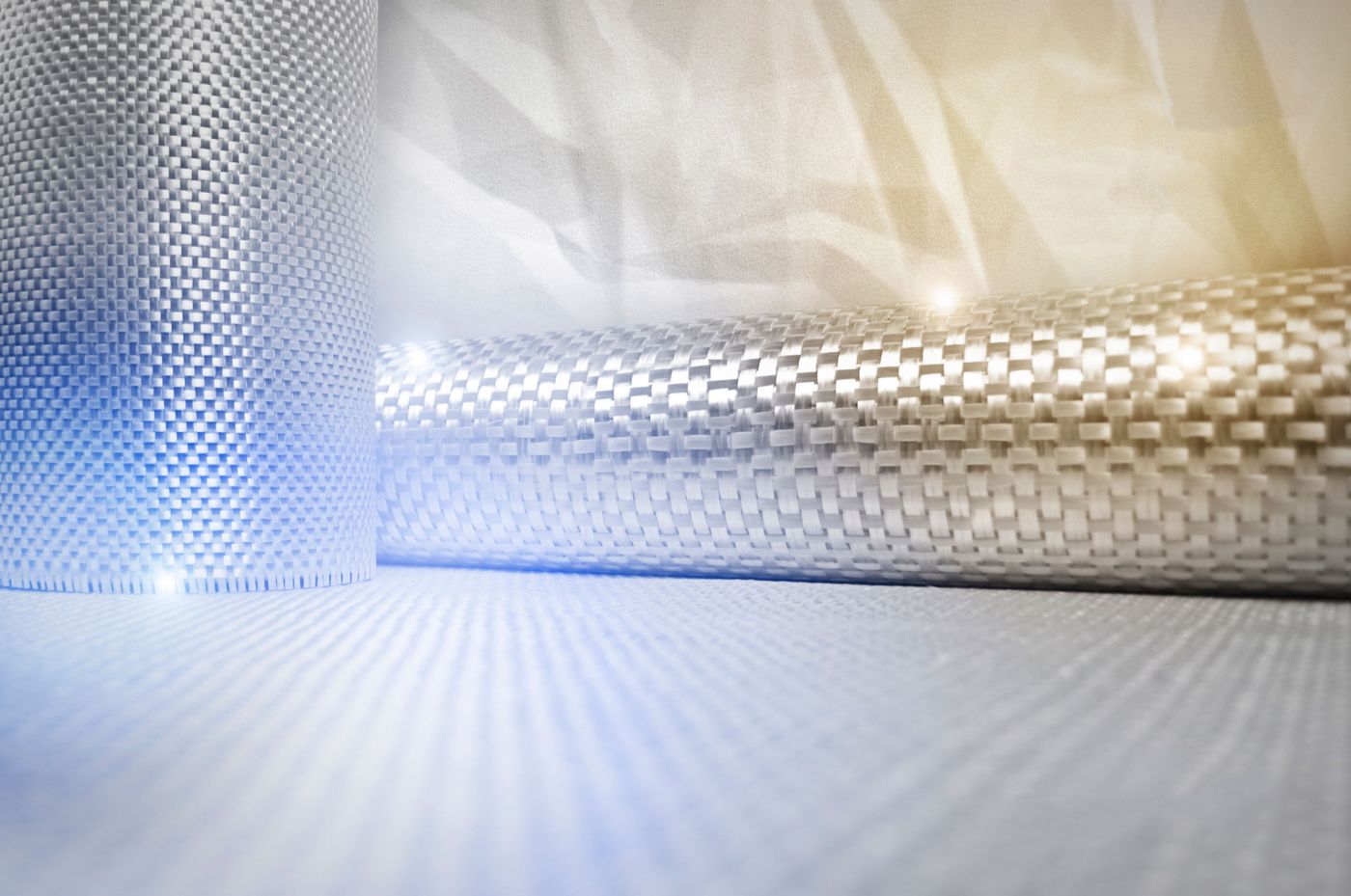

MÜHLMEIER COMPOSITES OFFER YOU A WIDE RANGE OF POSSIBLE FIBER PRODUCTS; WHICH ARE SUTIABLE FOR THE USE IN FLAME PROTECTION SYSTEMS AND ALSO ESPECIALLY DEVELOPED FOR SUCH USE:

CHOPPED STRAND MATS

Chopped strand mats consist of cut and non-orientated E- resp. E-CR-glass fibers, which are either bound chemically by a special powder- or emulsion binder or mechanically strengthened. Working in the well-known contact- or continuous processes. The mats are suitable for UP-, EP-, and vinylester resins.

ROVING FABRICS

Roving fabrics are technical flat constructions produced of E- or E-CR-glass direct roving, mostly woven to a stable compound in linen- or twill weave. Therefore most different combinations of area weights and area weight orientations (warp strengthened or weft strengthened) are possible.

Obviously all our roving fabrics are suitable for the most common resin systems.

MULTIAXIAL FABRICS

Multiaxial fabrics are also flat constructions and its different orientated fiber layers are „lying“ on top of each other and sewed up with each other. So the fiber tensile strength in all directions is used best. The adjustments reach from unidirectional in 0° and 90°, bidirectional in 0° and 90° to multiaxial in variable orientation of the single layers in angles of preferred ±45°, 90°, 0°. These highly complex flat constructions of glass fibers unique highest stability, longevity, and lightness in the production of fiber reinforced moulded parts.

FLOWMAT FR®

FLOWMAT FR® is an innovative triple compound of a knitted glass fiber core, embedded in two layers of chopped strand mats. It was especially developed for the working in closed processes like RTM or vacuum technics. The exclusive use of glass fibers and the so resulting excellent mechanical characteristics offer ideal suppositions in co-operation with the resin system to fulfill the ambitious international fire protection standards.